Buy Disposable Manufacturing Gloves

Buy Disposable Manufacturing Gloves Best Options

After trying many different type of gloves from amazon, finally found ones with good fit and quality. Would recommend!

Good size, not too tight, not too loose. Strong material, don’t rip like others I’ve used. Recommend

These gloves are thicker and well made. They fit snug, which I like. Met my expectations and would recommend.

Regarding manufacturing and factory work, safety is of the utmost importance. After all, it is necessary to ensure your and your employees' well-being to have a successful operation. From workplace health hazards that can lead to short-term injuries like slips and cuts to long-term risks like skin conditions or chronic diseases due to contact with hazardous chemicals - these are not desirable outcomes for anyone. Investing in disposable manufacturing gloves can help mitigate many potential accidents that often occur in a working environment, allowing you and your staff peace of mind when conducting any industrial task! With their comfortable fit, reliable protection from contamination, electrostatic discharge protection (ESD) from static electricity buildup on earthed surfaces, and excellent breathability qualities – disposable gloves offer so many great benefits when utilized correctly.

Importance of Manufacturing Gloves

Manufacturing gloves is essential, as they are a vital tool to help protect us from hazardous conditions. Gloves can shield the skin from potentially dangerous substances such as oil, fertilizer, fuel, and other chemicals. They also provide a barrier against microorganisms that may cause disease when exposed to open cuts or scrapes on the hands. In addition, gloves are often worn for protection in extreme temperatures and environments that could lead to severe burns or frostbite without proper shielding.

Furthermore, gloves play a significant role in occupational safety practices. Workers who handle sharp objects, toxic chemicals, or hazardous materials frequently wear protective gloves—whether a single glove made of plastic material or two layers of leather gloves—for extra protection against injury or contamination from their work environment. For instance, medical practitioners wear disposable latex-free vinyl examination gloves whenever handling patients with infectious diseases like HIV/AIDS to prevent the spread of any life-threatening illnesses through direct contact with bodily fluids or contaminated surfaces within an operating room setting.

In conclusion, manufacturing and wearing protective gloves has become an integral part of everyday life and work activities due to their numerous advantages that promote better health and safety standards while working at home or away from home; hence making them essential aspects of modern society today!

Types of Manufacturing Gloves

Manufacturing gloves are essential for keeping employees safe and protecting them from potential hazards during manufacturing. Many types of manufacturing gloves are available on the market, each designed with a specific purpose in mind.

Leather Work Gloves

Leather work gloves are one type of glove commonly used in manufacturing environments. They provide excellent protection from cuts and punctures and protect against hot surfaces. Leather is also highly durable, meaning it can be reused more times than other materials before needing replacement.

Chemical-Resistant Gloves

Chemical-resistant gloves are another popular choice in industrial settings where chemicals may be present. These types of gloves come in various materials, including rubber and neoprene, that provides excellent resistance to oils, acids, bases, and other caustic substances.

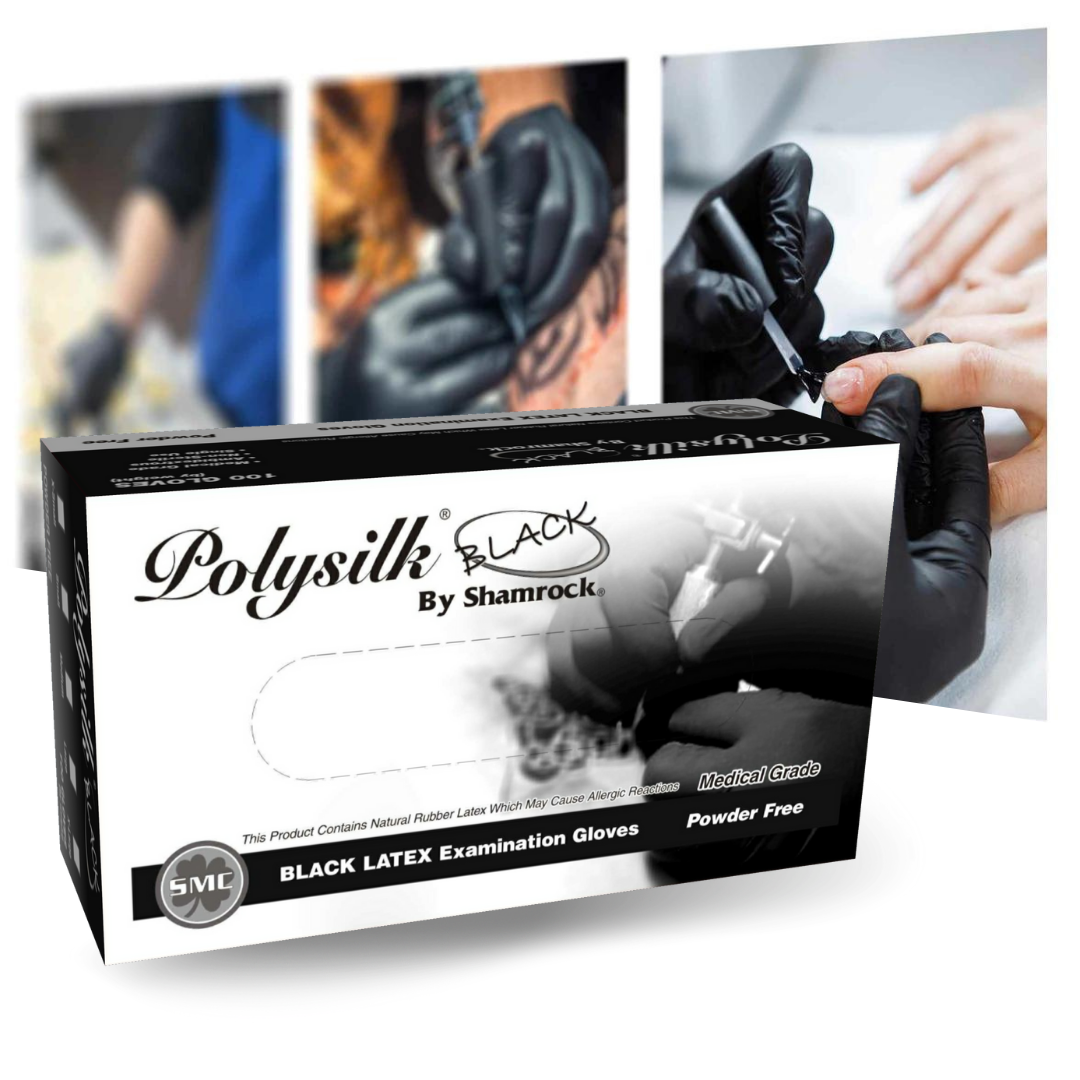

Latex Gloves

Disposable nitrile or latex gloves are also popular among manufacturers due to their ability to form-fit around a user's hands while providing superior grip strength when dealing with small parts or tools within the production environment. Disposables also help protect workers against infectious diseases as they create an effective barrier between the employee's skin and any contaminants that may have been handled by another person who came into contact with them before wearing them themselves.

Standards and Certification for Manufacturing Gloves

Standards and certification for manufacturing gloves ensure that companies produce safe and reliable products. The International Organization for Standardization (ISO) has developed guidelines and standards for designing, producing, shipping, distributing, labeling, and using personal protective equipment (PPE), such as gloves. These standards must be met to ensure high-quality PPE products are produced.

The American National Standards Institute (ANSI) is also a key organization regarding glove standards. ANSI provides general performance-based guidelines, which include warning labels, flame resistance requirements, physical testing protocols, chemical resistance requirements, electrical hazard evaluations, etc. The American Society For Testing And Materials (ASTM) is another popular standard when it comes to certification of the materials used in producing gloves like latex or nitrile rubber or polyvinyl chloride etc.,

Overall, various international organizations like European Committee for Standardization(CEN) and the British Standards Institute(BSI) provide essential guidelines related to production processes & product quality control parameters regarding different types of gloves available on the market today. In addition, some manufacturers also have their own certificate programs which guarantee the highest level of safety against contamination hazards.

Maintenance and Care for Manufacturing Gloves

The proper maintenance and care for manufacturing gloves are essential in order to get the most out of them. In general, a few basic steps should be taken when caring for your gloves.

- Read the glove's label and follow all instructions provided by the manufacturer to not void any warranties or rated wear times.

- Clean your gloves regularly with warm water and mild soap (or manufacturer-recommended cleaning agent). Be sure to rinse them thoroughly to remove all soap residue and allow them to air dry before reusing.

- Inspect your gloves frequently for signs of wear, such as fraying threads or cracks in the material that can lead to tears or other safety risks if left unrepaired. It's best practice to replace any damaged or aging pairs immediately rather than continue work with faulty protection gear which may otherwise put you at further risk of injury on the job site.

- Store your clean, dry manufacturing gloves in an area out of direct sunlight where they will not be exposed to extreme temperatures, moisture, oils, greases, and chemicals that could prematurely damage their integrity; this includes storing them away from open flames or combustible materials that could ignite from static electricity buildup within fabric-based products such as leathers used on many industrial grade glove models commonly found today's workplace environments..

- Regularly inspect interior liners for bacteria growth often caused by perspiration accumulation over time - a common problem among individuals who frequently wear safety gear throughout long shifts in busy factories - so as to keep workers safe against skin diseases like staphylococcus aureus infection (MRSA) which can sometimes occur due extended use without proper maintenance procedures being taken along the way. Following these steps is essential both from a safety standpoint and also from an economic one: properly cared-for equipment has been known last longer than improperly maintained ones!

Frequently Asked Questions

Which material is used for manufacturing of gloves?

Gloves are typically manufactured using latex, polyethylene, nitrile, and vinyl. Latex gloves are the most commonly used for medical purposes due to their superior strength and elasticity. Polyethylene gloves offer resistance to chemicals and cuts but lack flexibility. Nitrile is a synthetic rubber blend with superior puncture resistance; however, it can cause allergic reactions in some people. Vinyl is less durable than other materials but offers protection from liquid splashes, making it ideal for food preparation or light industrial work.

Where are gloves manufactured?

China is the world’s largest producer and exporter of gloves with production capacity accounting for around 60% to 70% of world output. It produces both low-tier low priced gloves with basic features and high-end fancy gloves made from materials like leather or suede for specialized markets like the medical and fashion industries.

What is the manufacturing process of surgical gloves?

The manufacturing process of surgical gloves is a multi-step operation that begins with collecting the necessary raw materials and components. The basic materials used in the production of latex medical gloves include natural rubber, filler material, chemical preservatives, color pigments, and antioxidants. After these materials are combined in various ways, they are then processed through several stages to creating a finished product.

Shop Disposable Manufacturing Gloves at Gloves.com

Getting the best Disposable Manufacturing Gloves has never been this easy! All you have to do is enter your information. Then, we’ll take it from there.

Here’s how the process works:

- Create an account if you are a new customer; log in if you’re an existing customer.

- Search Disposable Manufacturing Gloves at Gloves.com

- Add your chosen gloves.

- Proceed to checkout.

Yup, it really is that easy! So what are you waiting for? Order your electrical gloves from Gloves.com today!

Keep up-to-date with our guides and find the best glove options for your industry

Guides to help you choose

Best Gloves For Pesticides

Is There A Natural Latex