Chemical Resistant Gloves

Chemical Resistant Gloves Best Options

After trying many different type of gloves from amazon, finally found ones with good fit and quality. Would recommend!

Good size, not too tight, not too loose. Strong material, don’t rip like others I’ve used. Recommend

These gloves are thicker and well made. They fit snug, which I like. Met my expectations and would recommend.

Protecting the hands and wearing the proper personal protective equipment is essential when handling chemicals. Your hands are exposed to hazardous chemicals, which can lead to allergic reactions, irritations, or chemical burns.

Don’t take your and your employees’ safety, purchase high-quality and durable chemical resistant gloves from gloves.com. We have a wide selection of different types of gloves, all available in different sizes and colors sourced from reputable brands in the industry.

Our chemical resistant gloves are comfortable to wear, fit perfectly, and protect the hands from harmful chemicals.

Browse, select, and buy chemical resistant gloves now, only from a reputable store, Gloves.com.

What are chemical resistant gloves?

In general, chemical resistant gloves are types of gloves that protect the wearer from harmful chemicals. However, the type of chemicals the gloves can protect against vary depending on the material used. Therefore, it is necessary to check the type of chemicals you and your employees are handling and exposed to, then narrow down the materials that can provide the necessary protection.

Types of chemical resistant gloves

There are different types of chemical resistant gloves, and each offers protection against varying chemicals. Here are the 5 most commonly used chemical resistant gloves.

Butyl Gloves

These chemical resistant gloves are made from flexible and elastic synthetic rubber. Which provides excellent protection against oxidation, abrasion, and corrosion. Butyl gloves can be used in low temperatures without affecting their flexibility and elasticity.

Butyl gloves protect the wearer from the following chemicals:

-

Alcohols

-

Aldehydes

-

Amine derivatives

-

Strong bases

-

Ketones

-

Esters

-

Rocket fuels

-

Peroxide

-

Concentrated mineral acids

These gloves are multi-purpose and highly durable. However, butyl gloves are more pricey and expensive than other chemical resistant gloves.

Latex Gloves

Latex Gloves have been widely used for centuries. It is a reliable, comfortable, elastic, and versatile type of gloves. However, if you or your employees have latex allergies, better skip latex gloves.

Latex gloves protect the wearer from the following chemicals:

-

Acetone

-

Nitric acid

-

Alkalis

-

Sulfuric acid

-

Hydrochloric acid

-

Formaldehyde

-

Methanol

-

Salts

-

Ketones

-

Sodium hydroxide

-

Potassium hydroxide

Neoprene Gloves

Neoprene Gloves were first made as an alternative to latex gloves. It offers excellent dexterity, comfort, flexibility, tear resistance, and durability. Neoprene gloves are reliable and can be used for high and low temperatures.

Neoprene gloves protect the wearer from the following chemicals:

-

Alcohols

-

Alkali

-

Organic acids

-

Hydraulic fluids

-

Aliphatic solvents

-

Gasoline

-

Oil

-

Grease

Nitrile Gloves

Nitrile Gloves is the most commonly used for chemical protection because of its superior protection against chlorinated solvents like perchloroethylene and trichloroethylene. However, they are not ideal for handling strong aromatic solvents, ketones, oxidizing agents, and acetates.

👉 For additional information read A Guide to Nitrile Gloves Chemical Resistance.

Nitrile gloves protect the wearer from the following chemicals:

-

Adhesives

-

Lubricants

-

Paint removers

-

Water repellents

-

Cleaning products

-

Sealants

-

Acids

-

Alcohols

-

Grease

-

Oils

-

Caustics

Vinyl Gloves

Vinyl Gloves are made from polyvinyl chloride also called PVC or vinyl. Vinyl gloves are commonly used in construction, maintenance, fishing, mining, fuel, and other industries.

Vinyl gloves protect the wearer from the following chemicals:

-

Ammonium hydroxide

-

Boric acids

-

Sodium hypochlorite

-

Ammonium hydroxide

-

Fluorites

-

Methanol

-

Household detergents

When are chemical resistant gloves used?

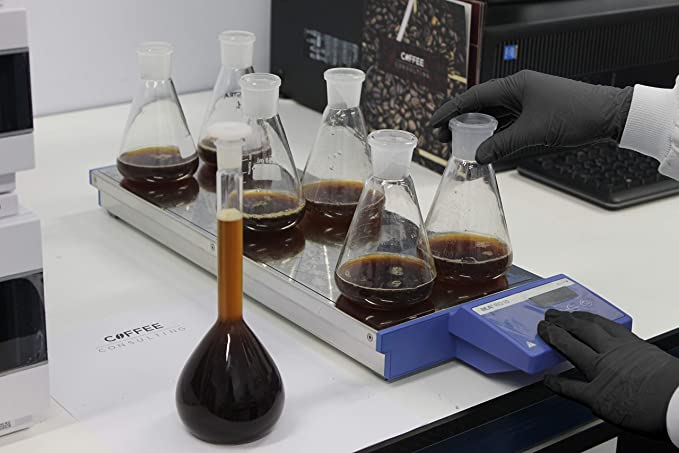

Chemical-resistant gloves are used when handling hazardous substances, such as solvents, oils, acids, or other corrosive chemicals, to prevent skin contact and minimize the risk of injury. They are essential in industries like manufacturing, laboratories, healthcare, and cleaning, where workers are regularly exposed to potentially harmful materials.

Do nitrile gloves protect against chemicals?

Yes, nitrile gloves offer protection against a wide range of chemicals, including oils, greases, and some acids, making them a popular choice for many industries. However, their effectiveness depends on the chemical being handled, the duration of exposure, and the thickness of the glove.

For highly corrosive substances, more specialized gloves may be required.

What gloves should you use when using chemicals?

The choice of gloves depends on the specific chemicals being used. Nitrile, neoprene, and butyl rubber gloves are commonly used for general chemical protection. For more hazardous chemicals, such as strong acids or solvents, specialized gloves made from materials like butyl rubber or Viton may be required.

Always consult a safety data sheet (SDS) for the chemical to select the appropriate glove material.

Factors affecting chemical resistance:

Even though chemical resistant gloves offer protection against different types of chemical substances, there are still instances where their protection is compromised. Here are different factors that affect the chemical resistance of your gloves.

Temperature

Some chemicals are handled at specific temperatures for easy and convenient management. However, not all materials are perfect for high or low temperatures. If you and your employees are working in either a low or high-temperature environment, it is best to look for chemical resistant gloves that can be used in that temperature.

This ensures you and your employees can work in these settings without compromising their safety, productivity, and efficiency.

Concentration

The concentration of chemicals can also affect the chemical resistant capabilities of your gloves. Highly concentrated chemicals can jeopardize the integrity of the gloves, especially if you and your employees are using low-quality gloves.

Always choose chemical resistant gloves from reputable brands to ensure their durability and quality.

Exposure

The length and how often the wearer is exposed to chemicals. If the wearer handles chemicals for a long duration, it is best to change gloves to ensure the chemical resistant gloves are not compromised.

However, the exposure can still affect its chemical resistance. For example, if the wearer doesn’t get in direct contact with chemicals, the protection of the gloves won’t be compromised even if they don’t replace it.

Storage

How the chemical resistant gloves are handled, stored, and maintained affects the integrity of the gloves. If your gloves are not stored properly, the gloves can turn brittle or prone to damage.

Always implement the proper storage procedures to ensure your chemical resistant gloves are safe to use.

Standards for testing chemical resistance gloves

It is important to check the behavior of chemicals during tests to ensure the gloves and materials can protect the wearer. Gloves are typically tested and rated in 3 categories:

Degradation

This pertains to the physical properties and changes during the tests. Some of the effects can include stiffness, swelling, wrinkling, color changes, or any other physical changes. The degradation tests and rating will depend on the manufacturers. There are no standard tests for the degradation test of gloves.

Breakthrough Time

There is a standard for this test called ASTM F739 Standard Test Method for Permeation of Liquids and Gasses. The breakthrough time pertains to the elapsed time from initial contact with the chemical on the glove’s surface to when the chemical is detected on its other side.

Permeation Rate

This measures the rate at which the chemicals pass the material of the gloves at a molecular level. The thickness of the material can also affect the permeation rate of chemical resistant gloves.

How to choose the best chemical resistant gloves

Not all gloves are made the same. Some chemical resistant disposable gloves are ideal for specific settings, chemicals, and applications, while others are not. Each type of chemical gloves has its own uses, benefits, and disadvantages.

To help you choose the best chemical resistant gloves, here are a few things and factors you need to consider before purchasing chemical gloves from us.

-

Types of chemicals handled

-

Material of chemical resistant gloves

-

Concentration of chemicals

-

Exposure to chemicals (frequency, duration, and nature of contact)

-

Temperature (chemicals and environment)

-

Length (hand, forearm, or arm)

-

Thickness

-

Grip requirements

-

Dexterity

-

Size, comfort, and elasticity

-

Additional protection or requirements

It is important to check these criteria before buying chemical gloves to ensure you and your employees are properly protected.

Proper use and maintenance of chemical resistant gloves

To ensure your chemical gloves are in excellent condition, here are a few safety tips and tricks:

-

Inspect the chemical resistant gloves: Check for tears, cracks, discolorations, tears, holes, swelling, or any physical damages. If you see any, it is best to replace your chemical gloves.

-

Wash your hands with soap and water: Before wearing gloves for chemical protection, always wash your hands with clean water and soap to ensure there is no contamination inside the disposable gloves.

-

Bandage cuts or scrapes before wearing chemical gloves.

-

Seal or close gloves tightly, outside: This ensures no chemical or harmful substances get inside the gloves from the sleeves. You can use tape or elastic if your chemical resistant gloves are loose.

-

Before removing the chemical gloves wash the gloved hands with soap and water. This ensures when you remove the gloves, you will not get in contact with any chemicals you are handling. Then, wash your bare hands again after removing the safety gloves.

-

Implement proper used gloves disposal: The used chemical gloves can be contaminated or compromised, it is best to throw them using proper disposal methods. Each establishment or company has its own disposal methods. Check the company’s disposal procedure.

-

Remove disposable gloves immediately when chemicals get inside: Wash your hands thoroughly using water and soap. Then, wear a new set of chemical gloves.

-

Never touch used or contaminated disposable gloves with your bare hands: There are specific disposal procedures for handling contaminated gloves. Always follow them to avoid problems, injuries, and emergencies.

For your and your employees’ safety, it is best to discard gloves with any signs of physical deterioration, this includes changes in color, texture, and elasticity. To keep your chemical resistant gloves in excellent condition, always store your disposable gloves away from extreme temperature changes, moisture, dust, and UV and ozone light.

For chemical gloves made from synthetic materials, store rubber chemical gloves in a cool and dark room with proper ventilation and low moisture. Never store rubber safety gloves in extreme temperature settings, both low and high. Also, ensure your gloves are not exposed to direct sunlight or any lights.

To learn more about the proper storage of chemical resistant gloves, always check the manufacturer’s guidelines, recommendations, and suggestions.

Limitations of chemical resistant gloves

No gloves can provide 100% guaranteed protection. All types of chemical gloves deteriorate and degrade in time, especially if they are not maintained and stored correctly. Hence, there are limitations to using chemical resistant gloves, here are a few.

Type of Chemicals Handled

Each type of material can only provide protection for specific chemical substances. Some materials are weak against others. Always check whether your chemical resistant gloves can provide the needed protection against the chemical you and your employees are working with. This ensures no accidents, injuries, or problems will occur during the production or handling of chemicals.

Degree of Hazard

Always conduct a hazard assessment test prior to using certain chemical resistant gloves. This is very important if you are trying out new chemical gloves. The degree of hazard and toxic properties are identified during these tests and can guide you in choosing the best chemical resistant gloves that fit the chemicals or chemical combinations handled in your company or establishment.

Allergies

Every person has their own skin conditions. Some people are allergic to specific materials of chemical gloves, for example, latex gloves. Check whether you or your employees are allergic to latex. If yes, go for synthetic materials which can provide the same level of protection or even better against the chemicals you and your employees are handling.

Shop Chemical Resistant Gloves at gloves.com

Do you handle chemicals on a daily or regular basis? Order the best disposable gloves for chemicals from gloves.com today! We feature different chemical gloves made from various materials. Whether you are searching for latex, nitrile, or vinyl gloves, we got you covered!

We made the ordering process quick, easy, and very convenient. Here’s how:

-

For new customers, create an account. This will make repeat orders easier. For those with an existing customer, log in to your account.

-

Browse through our high-quality chemical resistant gloves.

-

Search and select your disposable gloves.

-

Choose the right size.

-

Add safety gloves to your cart.

-

Proceed to checkout.

This a quick, easy, and very convenient way to order durable and quality chemical resistant gloves from reputable brands in the industry!

Keep up-to-date with our guides and find the best glove options for your industry

Guides to help you choose

Best Gloves For Pesticides

Is There A Natural Latex